In the midst of the global health crisis, the argument of which PPE offer the most protection has been widely discussed. Because of this, it seems fitting that OSHA has recently announced some changes to its Respiratory Protection Standard, part of its extensive governance to continue promoting workplace safety for all employees. As TSI Incorporated originally reported, these changes will affect the Ambient Aerosol Condensation Nuclei Counter (CNC) Quantitative Fit Test (QNFT) Protocols in 29CFR 1910.134, Appendix A.

At the center of these changes are two kinds of respirators: Full-Facepiece and Half-Mask elastomeric respirators, and Filtering facepiece respirators. Three studies published in a peer-reviewed journal led to these changes, and found extreme similarities to the original Ambient Aerosol CNC QNFT protocol. Before these protocols were in place, testing took approximately 7.25 minutes, but that has been streamlined to reach an average of approximately 2.3 minutes.

The Concern with Qualitative Fit Testing

As with every human-run process, Standard Qualitative Fit Testing allows for a significant margin of error because it is subjective. That means it relies on the user’s senses to respond to and relay information during the typical testing methods (Saccharin and Bitrex). Qualitative methods are still in compliance with OSHA, but there are newer and safer methods of conducting respirator fit testing.

PortaCount and the Benefits of Quantitative Fit Testing

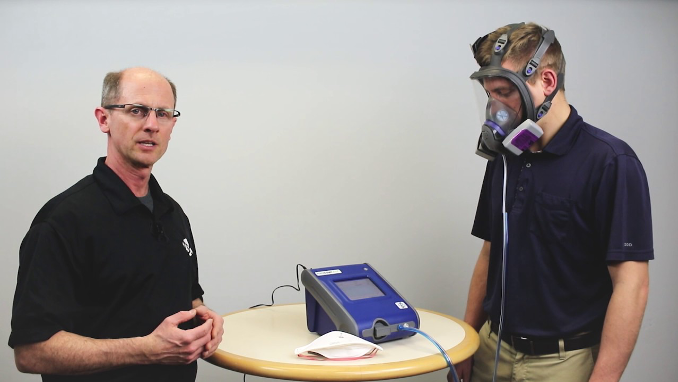

A popular technology helping pursue quantitative fit testing—an objective method that minimizes human error—is the PortaCount Respirator Fit Testers. This technology assesses the adequacy of respirator fit by numerically measuring the amount of leakage into the respirator.

This method uses a machine that measures particles, effectively removing the subjective nature of a standard qualitative fit test. Studies have show that quantitative fit testing like this achieves higher Simulated Workplace Protection Factors (SWPF) than qualitative methods for N95 filtering face pieces.

This method uses a machine that measures particles, effectively removing the subjective nature of a standard qualitative fit test. Studies have show that quantitative fit testing like this achieves higher Simulated Workplace Protection Factors (SWPF) than qualitative methods for N95 filtering face pieces.

The PortaCount can also test a variety of half and full-face respirators from all major manufacturers. The quantitative testing method is a safer approach, allowing fit test administrators to no longer rely on a person’s senses and self-reported feedback to determine if a mask fits. Other features of this new technology include real-time fit changes that can help users select the right mask and identify the best fit quicker. On-screen video animations help guide users while conducting the tests.

The PortaCount software is continuously updated and maintained to guarantee the most accurate results, and all data is securely stored and documented. The PortaCount administrator can see exactly when a test took place and by who, as well as when they another test will be needed.

Overall, the PortaCount is an exceptional machine that offers near fool-proof fit testing, eliminating the subjective nature of traditional qualitative fit-testing that can lead to discrepancies that could prove to be harmful to people and their surroundings. It helps protect workers and maintain OSHA compliance by providing accurate, real-time fit factors. And, of course, this technology is also incredibly useful during the current health crisis, potentially allowing front-line workers who require these types of masks and respirators to know they are getting the right level of protection.

Interested in the OSHA reports that led to these developments? Take a look at them here and here.

PortaCount Fit Testing Services Now Available

Please contact us today for more information and custom pricing options.